A common fault with these keys is that one of the buttons stops working. You can tell when this is a fault with the key rather than the car because the led stops flashing. If both buttons have failed then first try the obvious and test the battery and make sure the contacts are clean. If so then you need to resort to one of two drastic solutions; buy another one (about £130) or repair it.

This is the type of key we are talking about, it is the type with two buttons and the safety slot in the end, not the proximity type. There may be other models that use a similar key, I have seen one with three buttons for instance, but I don’t know if they have the same weakness. The fault with these keys is that they use surface mount micro-switches and the “lock” one seems to be on a vulnerable part of the board which perhaps flexes and it drops off. Often you can hear it rattling loose inside.

The tools you will need are a good strong Stanley knife, a soldering iron with a very small tip (1mm or less), some long or curved-nose pliers, a strong magnifier and some super-glue.

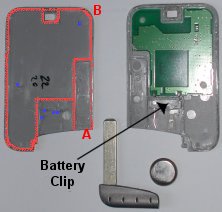

The first task is to get inside. These are not clip-together cases, they are glued all round and on some internal ribs as well. On the photograph of my one below (click for a larger image without my annotations), I have marked the glue lines in red. The blue dots are unglued guide posts. With a strong Stanley knife and starting at the point marked “A” you can carefully cut along the edge, try to cut if you can as it doesn’t split very well—and watch your hands as the blade is liable to slip. When you reach the first bend “B” go back and do the first internal rib, then you can move round peering in the crack to see what to cut next. Be careful not to damage the components or the circuit board. A close inspection of the pictures shows the things to avoid, it is really a matter of patience, care and brute force.

As you can see, mine opened upside down, so the next step is to cut under the battery clip to separate the circuit from the case; I used a small kitchen knife to get in there.

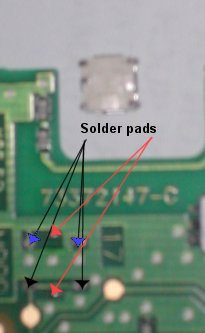

So you should now have all the parts laid out including a loose button switch. This switch has a contact on each corner, two fold-under lugs to hold it together and two other lugs to help it stick to the board (ha! ha!). Sorry, the resolution of our camera is not good enough to see this detail. Near the centre of the circuit board you have a corresponding space with two pads on the earth plane at the top (arrowed blue), two on a track leading to the IC at the bottom (arrowed black) and two isolated holding pads (arrowed red). The orientation of the switch is important, the wrap around lugs MUST be to the sides.

With your fine tip soldering iron, clear up and tin all the contacts on the switch. Similarly clean the circuit board pads. You are well away from any delicate components here so there is not a lot of risk. Make a small solder bead on each pad. When I say small I mean small; I used a jewellers eyepiece to see what I was doing, scary with a hot soldering iron inches from my face.

Now lay the switch on top and test that it works by holding the battery in, and pressing the button. If you get the switch the wrong way around, the light will be on without pressing the button. Satisfied that it works you can solder the switch into place—holding the switch down with long pliers, touch the soldering iron to each corner and the top/bottom edges to get the solder to bridge the gap in six places. You may need to go round more than once as the component beds down to the surface. Test it again. As a final touch, I dribbled a bit of super-glue under the switch as an attempt to hold it more securely.

Now clean up the plastic parts with a knife, removing all loose bits and get the halves to mate together tightly without the circuit. You will also need to clean up the plastic part of the battery clip. Lay the circuit into the back cover, there should be two positioning pegs to hold it in place. Apply a drop of glue to the battery clip to secure it and leave it for a few moments to set. Finally run a bead of glue around the outside edges and the main internal rib, bring the parts together and clamp (clothes pegs) or weight it until it sets. How many of the original lines you do depends on if you are likely to want to undo it again but I would suggest omitting the front of the battery clip.

For the technical, the numbers on the components are: the big round piece (transmitter coil?) is 50751, the DIL package (encoder?) is Phillips PCF7947AT with other numbers 16793102 and DnD00350. The small silvery unit (oscillator crystal?) has EPC05, R727 and M5MN. A Google search didn’t turn up much.

Webmaster

Webmaster

Just followed the instructions. Works a treat. Thank you very much.

was just wondering cause my keycard has given up the ghost when you place the card in do you get ignition lights as mines lights up but when you press the start button you get nothing you can hear it wanting to start but no joy also i can bump start mine just wondered if it was the same fault

Stuart, when the card is not working, it doesn’t even try to start. If the engine turns over but doesn’t start (like mine has taken to doing recently) then it is a fault somewhere else. In my case, I suspect a blockage on the fuel line as there is no smell of petrol (outside) while it is trying. In the old days you would check the coil etc. as well but I have no idea now.

My keycard wouldn’t lock the car, rattled inside etc so followed the repair process & now the car locks once again – both buttons working OK. Unfortunately however I can no longer start the engine. Instruments all light up but pressing start button does nothing. Does the keycard need resetting in some way? Thx, Mark

Does any one know where I could get hold of some sort of accessory that attaches to the key card, so that you can put other keys on???

Got 52 plate laguna with key-hole being at the end you insert.

Cheers

Scott, I don’t think there is such a thing. My local garage attaches a label using fine string that that is ok; doesn’t gum up the works. I can’t think of any way of attaching something to the other end – though I suppose you could drill a hole, there is plenty of room. Be careful though!

Rick,

Thanks for your reply mate.

However, I was in the local Renault garage recently and the girl behind the reception mentioned some sort of rubber/silicon/casing end cap that fits on or over the end of the key card that doesn’t go into the slot.

There is a hole on this cap thing that allows you to secure a set of keys to.

She did say however that Renault no longer supply them……

She also mentioned that Halfords could be a good shout.

Great stuff Scott. Post back if you find anything. It clearly looks like a point that was never thought through by the designers.

Just found this on the web – worked perfectly. I’ve got one of the 3 button keys – you just have to be a bit more careful when cutting it apart due to the extra stuff inside.

Thanks for the guide!

The clip that Scott mentioned is available on Ebay for less than a fiver posted, here is a link

http://cgi.ebay.co.uk/renault-laguna-key-card-clips-x2_W0QQitemZ230307304780QQcmdZViewItem?hash=item230307304780&_trksid=p3286.c0.m14&_trkparms=72%3A1301%7C66%3A2%7C65%3A12%7C39%3A1%7C240%3A1318

Brilliant, just bought a used Laguna from a dodgy garage and this was one of the first things that started to niggle…quick internet search found this site, quick trip to B&Q for a soldering iron (never soldered anything before in my life!) and key card fixed in 2 hours.

Did burn some holes in my carpet and kitchen worktop, oh and stabbed my thumb with the Stanley knife and that part is hard…as the man says….be patient. But all of it worth it for the 130 quid stealership money I don’t have to pay out!

Thankyou so much for the well put together guide….I so love the internet!

dont understand took card apart but both buttons are still workin as red light is still going red….but wont open car doors…..very strange

Thank you for the advice! Worked perfectly for me- I managed to cut the key open /not easy, demands nerves/. Button needed soldering as desribed. Unfortunately, I could not do the soldering myself- I have no idea how did you guys manage, if you used home equipment. A friend, electronics pro did the soldering for me and I treated him a drink. LOL. I used epoxy to glue the card, next opening /hpe never/ will not be easier at all.

Hi i found these guys on the net & they are in london,fixed both my keycards for £25.00 each,saved me a fortune heres there site http://www.keycardrepairservice.co.uk ,well worth contacting if you dont want to attempt the repair yourself.

pauly………

Bought a Used Renault 04 in July 06 from camden dunstable. Have now gone through three keys a(a brand new onen only lasted 9 months at £160.00)

Service manager at Camden, said Warrnaty would not be because it has a slight crack around the button as if he had not seen that before as that what happens when all the keys fail

DONT BY A RENAULT

Worked for me but be VERY VERY careful you don’t dig too deep with the knife around the edge Upper side near “B”). I caught some small components on the board. wouldn’t work at first until I inspected and spent longer soldering three 1mm wide blocks back!! (175 Quid cheapest I was quoted for a new one!)

I’ve took it apart, got both butons working, but it will now not operate the car !! Any suggestions or ideas please ??????

Craig had same problem with mine see the black chip with 12 little legs on it some of them must be broken if that does not work . get a second hand card and solder this chip onto it be very carefull doing this

hi all ive just tried getting the key apart which i did in the end but i have broken the battery feet of doh can i solder them back on also the buttons seem find put only one works

It won’t be easy soldering the battery clip but you can try. Just don’t get the rest of the circuit board too hot.